Introducing the World’s first

biomimetic, tunable,

transparent, and reproducible

3D cell culture well plates.

lates

Technology

We make patented "collagen-like" scaffolds for next generation 3D nanofiber well plates.

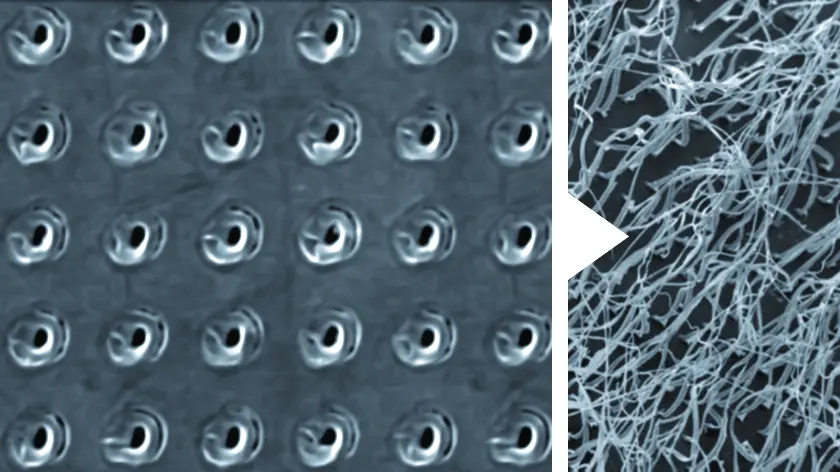

A reusable template or mold is created by drilling billions of cylindrical nanoholes into a glass substrate, placing each hole with 50 nm precision.

The template is used to emboss nanofibers onto a polymer film. The nanofibers form reliably in the template holes, enabling highly precise and customizable fiber spacings and patterns.

Fibers are integrally attached to the film and remain fixed in place.

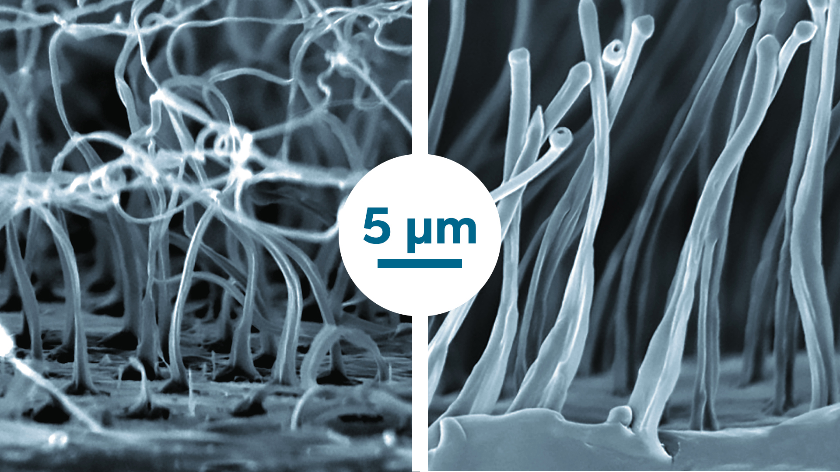

With further processing, fiber diameter (and therefore stiffness) can be increased from a wispy 50 nm to well over a micron.

This provides the means to customize microenvironments across the entire range of collagen fibrils found in biological scaffolds.

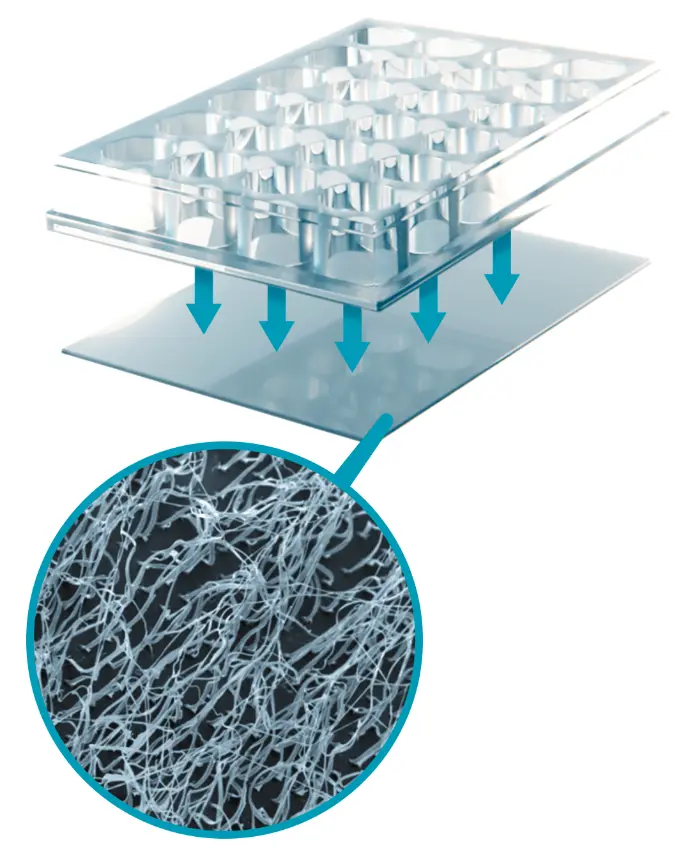

Our 3D nanofiber scaffolds are sealed to the undersides of 2D well plates, which are molded without bottoms but otherwise have standard well plate dimensions.

This allows cell culture to take place in the biomimetic 3D nanofiber microenvironments created by our scaffolds without the need for hydrogels.

These microenvironments are tunable for each application by adjusting the hole patterns and sizes in the template and can be reproduced with high precision.

USF scaffolds are embossed on 125 µm thick polycarbonate cover slips so that cultures can be easily monitored in situ with inverted microscopy.

Other form factors will be available in the future to meet the evolving needs of our customers and the broader marketplace.

3D cell culture scaffolds made from USF nanofilms offer inherent advantages over current 3D scaffolds.

Biomimicry

Collagen-like fiber sizes, spacing/density, orientation, and stiffness gradients create more natural 3D microenvironments for cell culture.

Reproducibilty

Precise control over fiber spacing, size, and stiffness can significantly reduce assay and process variations often caused by the randomness of existing technologies.

Scalability

Batch-producible for fast prototyping, small form factors, and custom lot sizes.

Continuously producible in unlimited quantities, potentially available in rolls wider than 30 cm.

Tunability

Fiber spacing/density and patterns (precisely tunable now) and diameter, shapes, and materials (tunability demonstrated but not currently offered as standard options) can be customized to optimize conditions for different cell types, with potential to promote:

- Cell health outside the body

- Cell-cell interaction

- Adhesion

- Stem cell maintenance or directed differentiation

- Guided cell growth, including linear alignment

- Other specific cell behaviors as needed

Usability

Compatible: Works with standard lab equipment and protocols. Can be functionalized using standard techniques, thin coatings, reagents, or other materials.

Hydrogel-free: Eliminates the need for hydrogels.

Accessible: Open structure allows 360-degree access to cells for nutrients and biochemical signals.

Transparent: Enables in situ imaging for live cell observation.

Convenient storage: Can be stored at room temperature with an extended shelf life.

Versatile: Can be adapted to different form factors beyond well plates, including T flasks, bioreactors, and parallel flow devices.

We can help you achieve your objectives.

Here are two ways to get started .

Sign up to receive free “tuning” well plates

Visit our "Protocols and Best Practices" page to see if optimal fiber densities or other characteristics have already been identified for your application -- by us or members of our community.

If an established protocol exists, you can begin directly with single-density well plates or imaging dishes using the appropriate pattern. For applications where optimal conditions are still being refined, our free “tuning” well plates are designed to accelerate discovery and inform the development of best practice protocols over time.

We'll then arrange a call to discuss best initial protocols. Each tuning well plate allows you to test six different fiber densities or patterns simultaneously under otherwise identical conditions. Once you have results, we ask that you share your feedback with us so we can help interpret the outcomes and refine next steps for your specific application.

Depending on your results, you can then either proceed with single-density plates optimized for your application or we can work together to further optimize as warranted.

Contact us to discuss your needs

There is potential to customize microenvironments and form factors for your application.

Click above to arrange a meeting to discuss.

FAQ’s

Yes. In addition to other intellectual property in the U.S. and abroad, we have broad patent protection for both our foundational technology and its application to biology, including U.S. Patents 11,667,062, 11,155,007, and 10,941,380. Other patents are pending.

Our nanofiber platform is designed to deliver both tunability and reproducibility, with continuous improvements being made and near-term priorities placed on the parameters that most strongly influence biological outcomes. Over time, we expect to provide highly tunable and reproducible control across all key structural parameters and to expand material options to enable application-specific control of properties such as stiffness, wettability, and cell adhesion, in a disciplined and application-driven manner.

We provide highly reproducible control of fiber spacing, density, and pattern, which are tunable by design and reproduced reliably within and across well plates. Fiber spacing can range from below 3 microns (approximately 110,000 fibers/mm²) to arbitrarily large spacings or custom patterns.

Fiber diameter is also highly consistent within a given configuration and from plate to plate. While diameter is not currently offered as a selectable parameter, the diameters used in our standard configurations fall within the central range commonly reported for natural collagen fibrils. Diameter tuning has been demonstrated and may be pursued through focused, application-driven partnerships.

Fiber height is not currently emphasized as a tuning parameter, as most applications are tolerant to variation across the range produced by our standard nanofiber configurations.

Yes. Patterns can be varied from section-to-section or even fiber to fiber. Each fiber can be placed exactly where it is needed to optimize cell behavior for any given application. Corn row patterns are great for aligning neurons, fibroblasts, or other cells.

Yes, we have demonstrated the ability to control fiber stiffness by modifying fiber diameter and material. For now, we are providing PCL fibers in the couple hundred nm range with high reproducibility within and between plates.

Our nanofiber scaffolds are currently made from polycaprolactone (PCL) on optically clear polycarbonate (PC) film substrates. The thickness of the PC is 125 microns, the equivalent of a #0 coverslip. Cells in the well bottoms only contact PCL, which is a bioabsorbable polymer commonly used in FDA-approved in vivo devices. Our well plates are also made from high quality PC. Our imaging dishes are initially made from medical grade polystyrene, but we expect to move to high quality PC over time.

Yes. A wide range of polymers have been used for nanofilm production, and others can be developed for future applications. Our technology is generally compatible with most thermoplastics and some thermosets.

No, hydrogels are unnecessary. Our collagen-like nanofibers already provide a superior 3D microenvironment.

Yes, USF nanofilms are compatible with common coatings, poly-amino acids, and proteins.

Yes. Our well plates are made to standard dimensions and are compatible with liquid handling systems, microplate readers, robotic systems, and other standard lab equipment.

Yes, cells can be viewed in situ through our optically clear well bottoms. The polycarbonate is equivalent to a #0 coverslip specifically for inverted microscopy.

Not yet, but we plan to offer sterile versions in the future. The nanofiber scaffolds are produced from molten polymer at >90°C and attached to well plates in a clean environment but are not yet certified sterile. We recommend cleaning with 70% ethanol/water solution followed by ultrapure water rinsing before use. Once wet, fibers should remain wet to avoid changes in the microenvironment upon drying.

Yes, our nanofibers are integrally and permanently attached to the underlying substrate. They are extremely difficult to remove, even with a razor blade. PCL fibers are bioabsorbable and may eventually degrade in vivo over weeks or months.

Yes, they can be stored at room temperature. While accelerated aging tests have not yet been conducted, we expect them to age similarly to standard 2D well plates.

Yes, other formats can be developed as needed. We will expand our offerings when there is sufficient demand.

Yes, our nanofiber scaffolds can be integrated into various formats, including imaging discs (available now), T flasks, petri dishes, bioreactors, and parallel flow devices. We can batch-produce or scale up with roll-to-roll methods, producing scaffolds in widths greater than 30 cm. We welcome partnerships to develop applications for different needs.

Yes. We are happy to discuss custom solutions, but we will need to prioritize based on complexity and potential impact. If you're interested in customization, contact us to arrange a discussion.